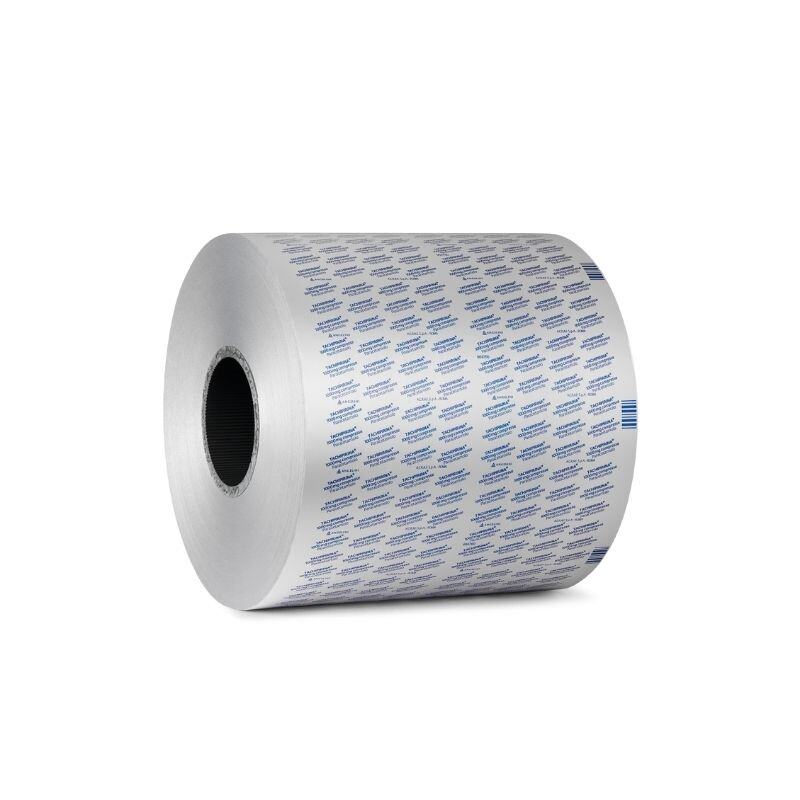

Printed aluminium

Aluminium offers protection for your products and safety for your consumers.

Aluminium must not only protect and preserve the properties of the product, but also guarantee high hygienic characteristics, protecting drugs from external contamination and prolonging shelf-life.

As primary packaging, it must provide protection against external factors such as moisture, light, oxygen, and microbiological contamination.

- Available in 20, 25 and 30 µm thicknesses

- 7 and 20 g/sqm PVC/PVDC thermo-lacquering

- Certified low-migration inks for pharmaceutical applications

- Completely nitrosamine-free manufacturing

- We sell neutral aluminium from certified manufacturers

PVC

In the pharmaceutical industry, PVC is the most commonly used forming material for blister pack production.

Extremely flexible in terms of specifications and compositions, it provides high levels of product safety and protection, while also ensuring optimal manufacturing speed and efficiency.

PVC does not contain any plasticisers, offering good structural rigidity and physical protection for the contained pharmaceutical doses, while still allowing easy drug dispensing.

Extremely flexible in terms of specifications and compositions, it provides high levels of product safety and protection, while also ensuring optimal manufacturing speed and efficiency.

PVC does not contain any plasticisers, offering good structural rigidity and physical protection for the contained pharmaceutical doses, while still allowing easy drug dispensing.

- Suitable for direct contact with drugs and food

- Available in different colours, as well as transparent

- Easy to pair with other polymers

ColdForm

COLD FORM (CFF) is an excellent multilayer structure designed for a range of pharmaceutical and generic products that are characterised by hygroscopicity or light sensitivity, and therefore cannot be adequately packaged using low-barrier plastic films.

- Absolute barrier to moisture, air, gases and light, maximising forming capabilities without fractures

- Extended shelf-life and high resistance to long-term delamination

- PA 25 μy - Alu 45 μy - PVC 60 μy