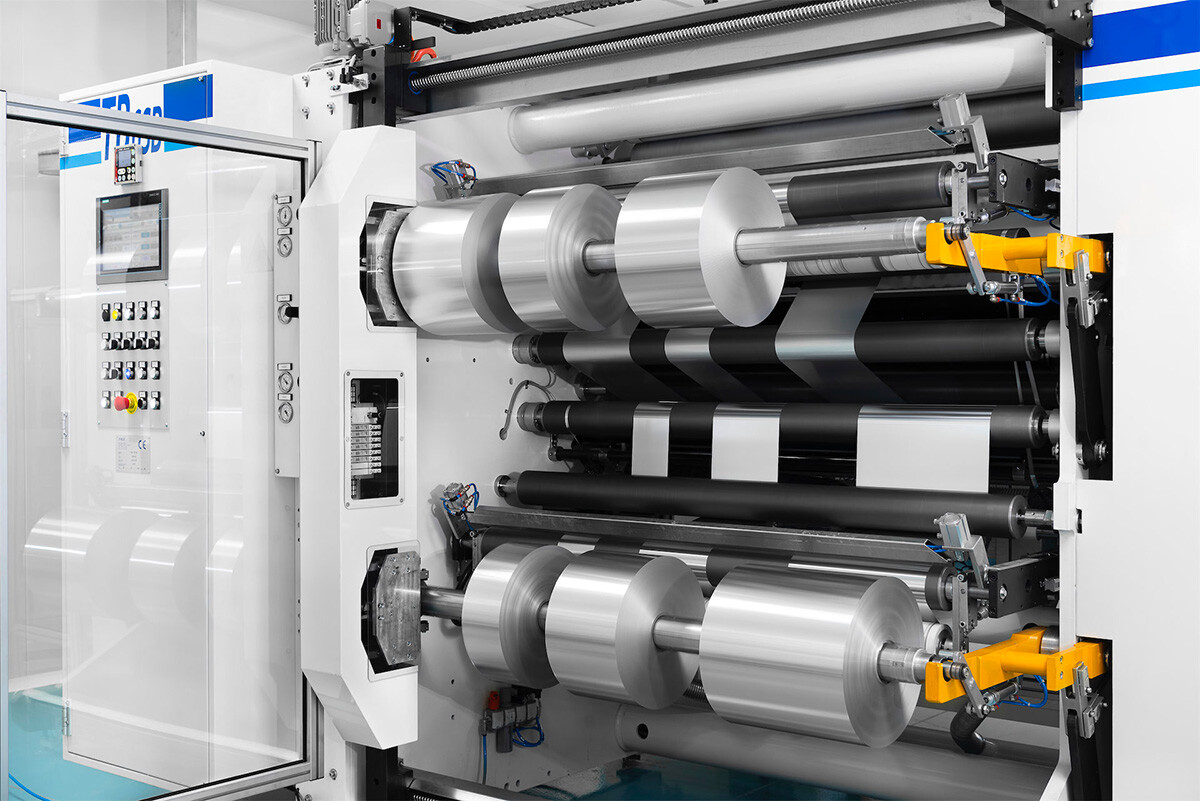

Manufacturing area

Every step of production takes place in an ISO 8 certified clean room, where humidity, temperature, and particle count are constantly monitored.

The three production lines currently in operation use digital printing technology and UV-LED drying systems, employing low-migration and solvent-free inks, helping to reduce environmental impact.

This type of printing electronically converts the artwork into a digital polymer, transferring its dithering onto the aluminium by means of small ink jets.

With an immediate process, UV-LED curing systems eliminate the risk of counter-printing, improving ink adherence.

Zero environmental emissions from solvents.

An excellent alternative to traditional printing methods such as flexo and gravure, digital technology simplifies and speeds up machine set-up, offering a fast time-to-market as an additional major advantage.

The definition and quality of digitally printed aluminium are superlative, and meet the durability criteria and tests required by the pharmaceutical industry, while also ensuring excellent and consistent colour performance.

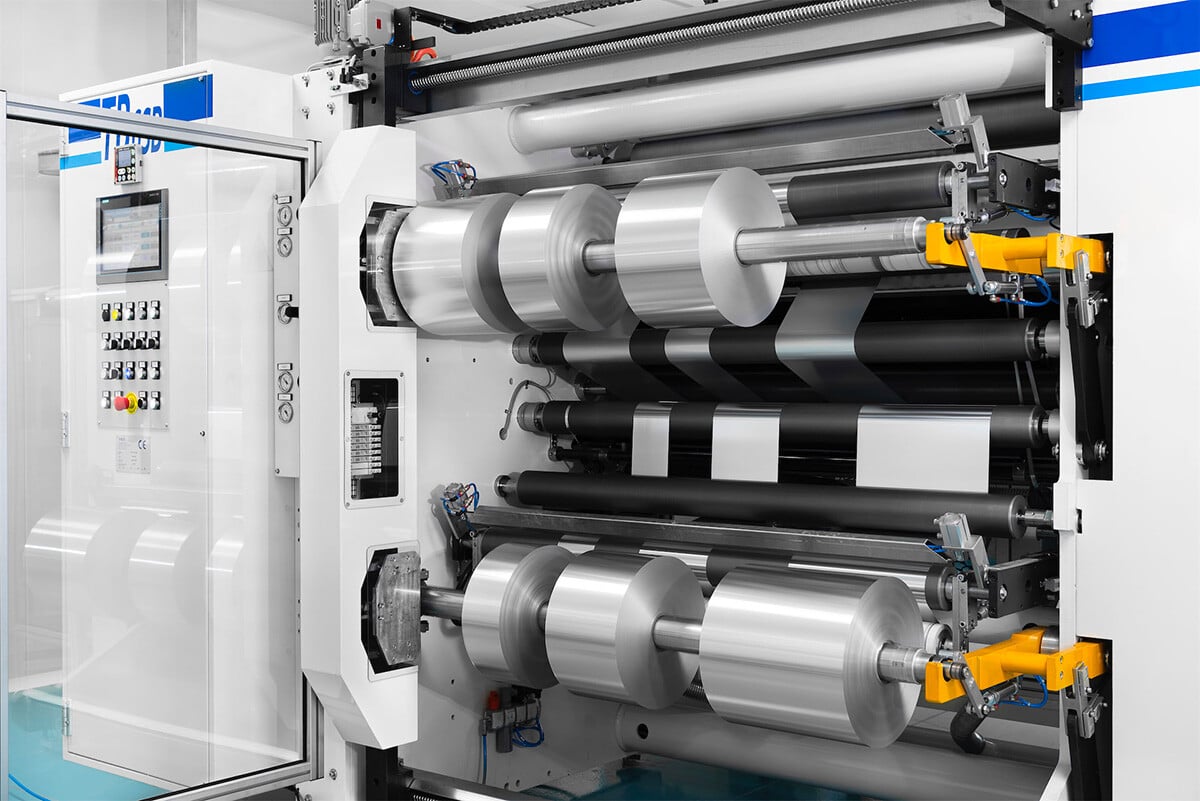

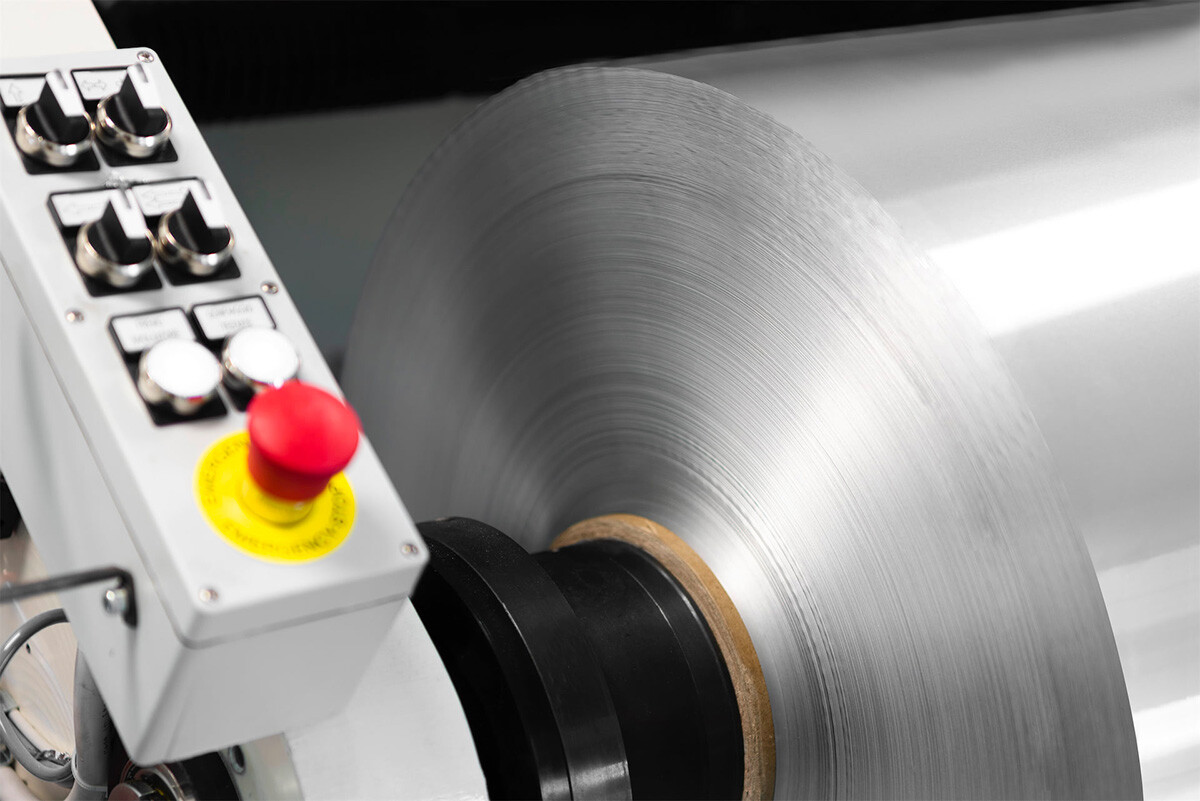

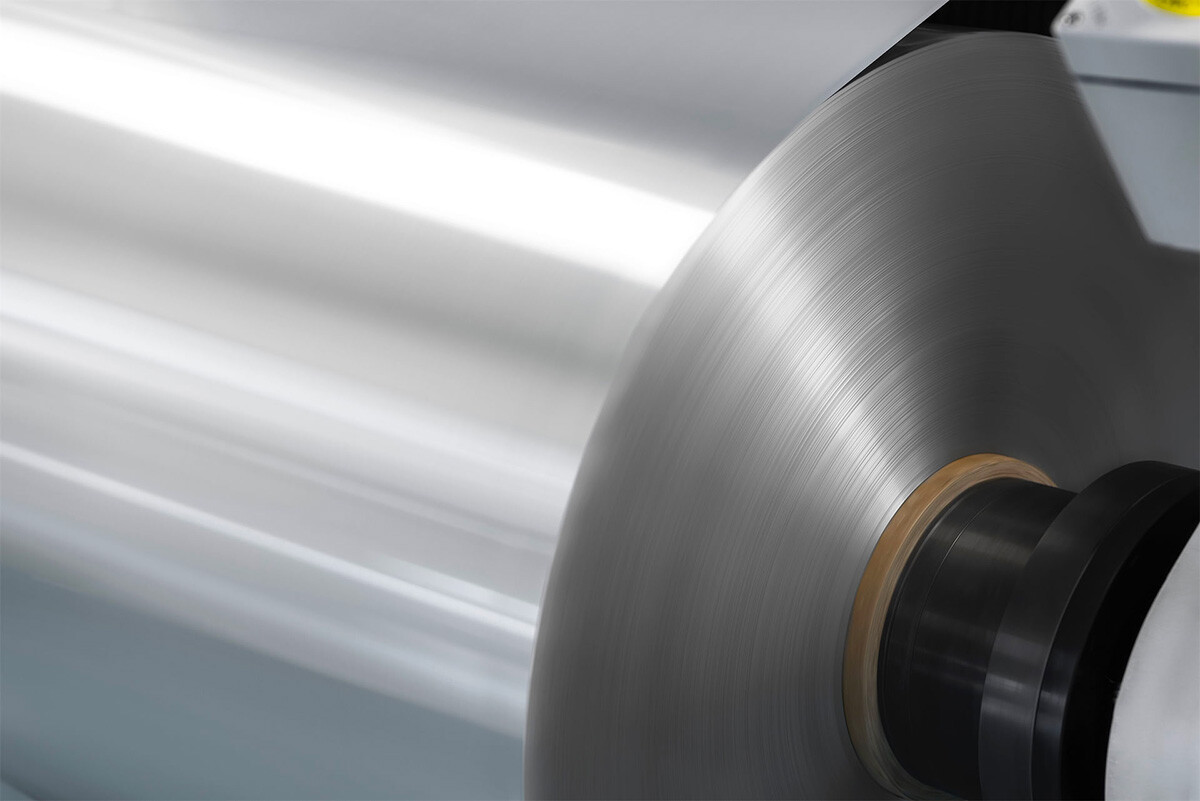

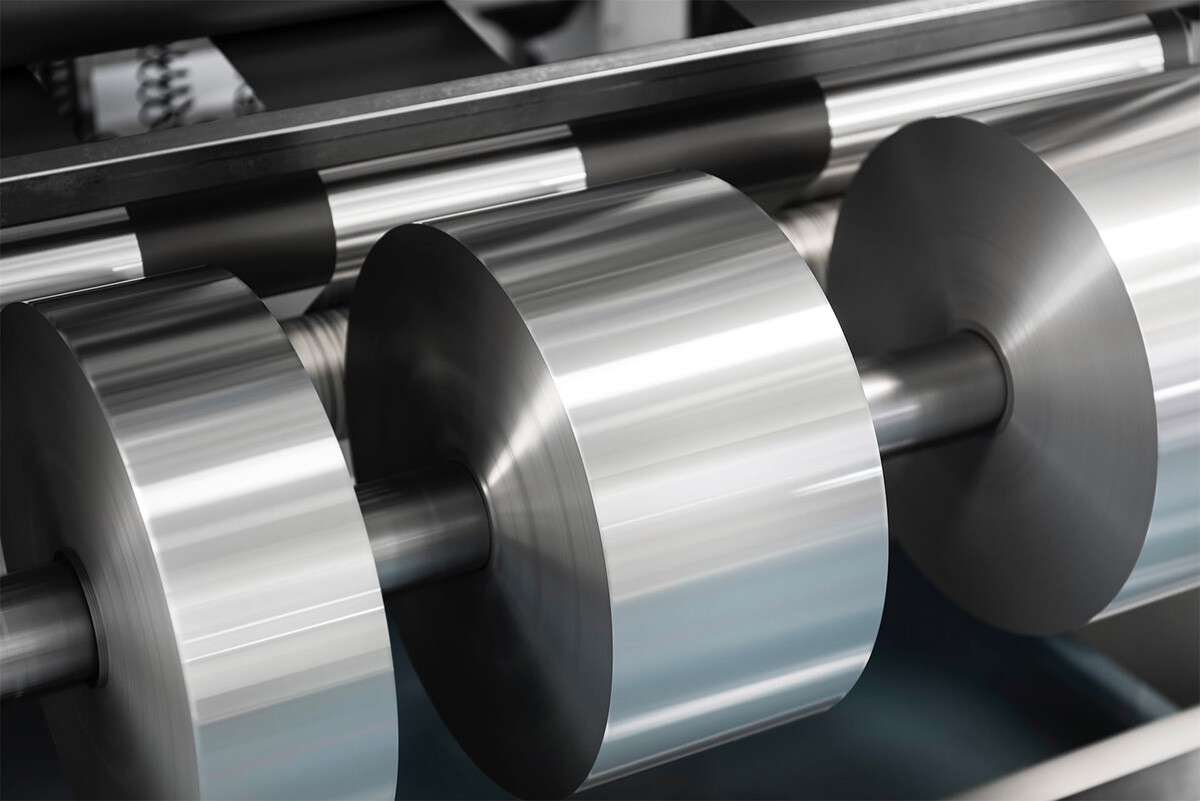

Sectioning plant

Aiming to always offer clients the utmost quality and service standards, Gualapack Pharma has invested in sectioning equipment that optimises material supply flows.

The plant, equipped with state-of-the-art technology including fully automated knife positioning and reel unloading of semi-finished material, is installed inside an ISO 8 certified clean room.

Besides being an added value in the day-to-day management of printing processes, the plant ensures constant availability of raw material, enabling high production output with maximum reliability.

Graphics department

Combining graphic design, pre-press and multi-level quality control, our graphics department provides files for high-definition printing, customised to clients’ needs.

It is responsible for analysing and evaluating files, laying out artwork for printing, and developing graphic files in accordance with technical specifications, layouts, and Latin, Cyrillic and Asian alphabets.

Thanks to its solid experience, cutting-edge equipment, and powerful and versatile software, our graphics department always guarantees the highest level of service in terms of precision, speed, and quality.